The development of individual customer specific tool solutions is one of Göltenbodt's most characteristic strengths. Each and every task means a challenge and commitment at the same time for us to find and provide a productivity increasing solution. Whether recessing attachments, longitudinal turning attachments, lifting attachments, outside grooving tool holder solutions, our team can rely on their decades of experience in the manufacture of customer specific products. We know the market environment just as well as the machine manufacturers and respective optimization potentials.

Contact us and tell us your task specifications.

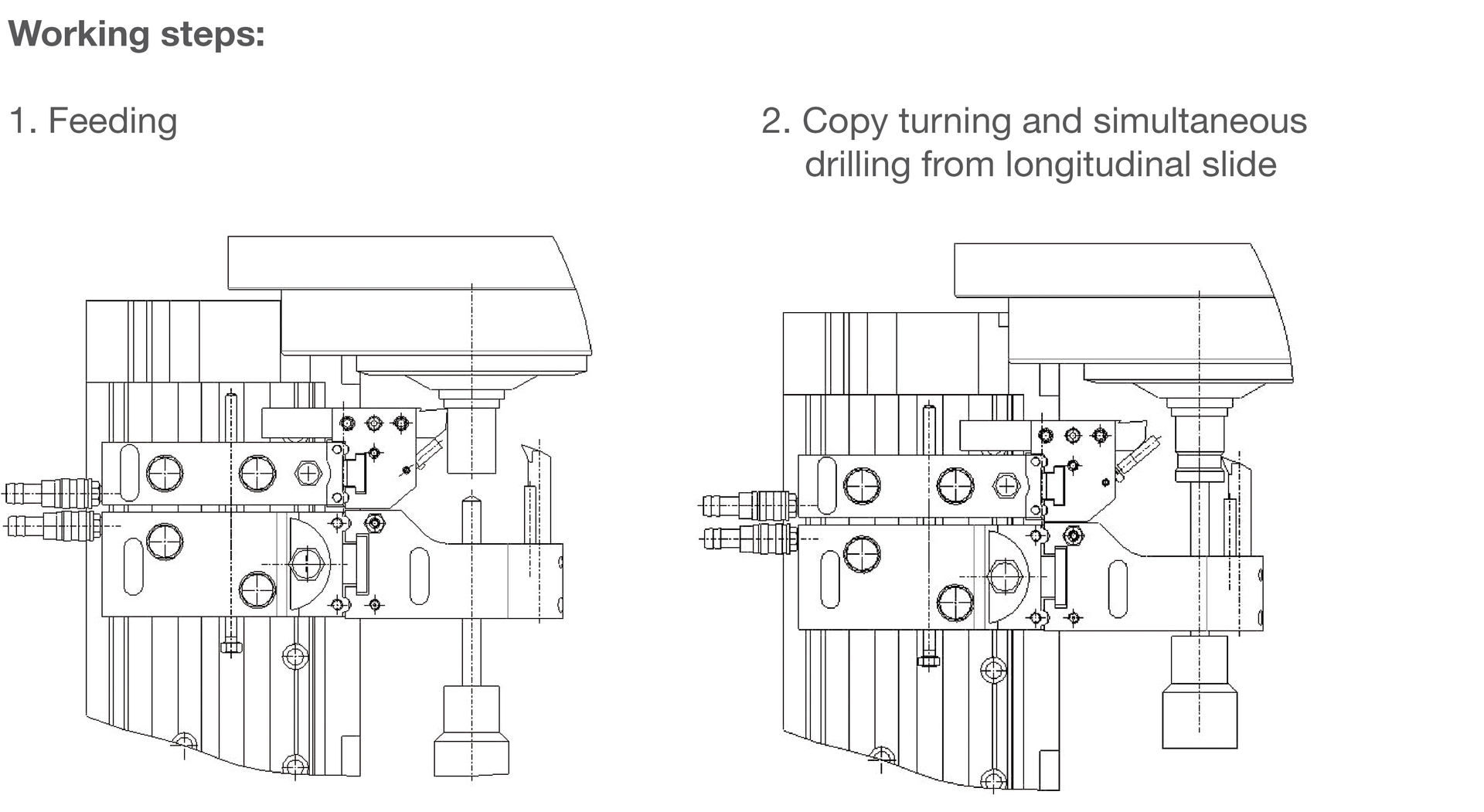

Best example 2:

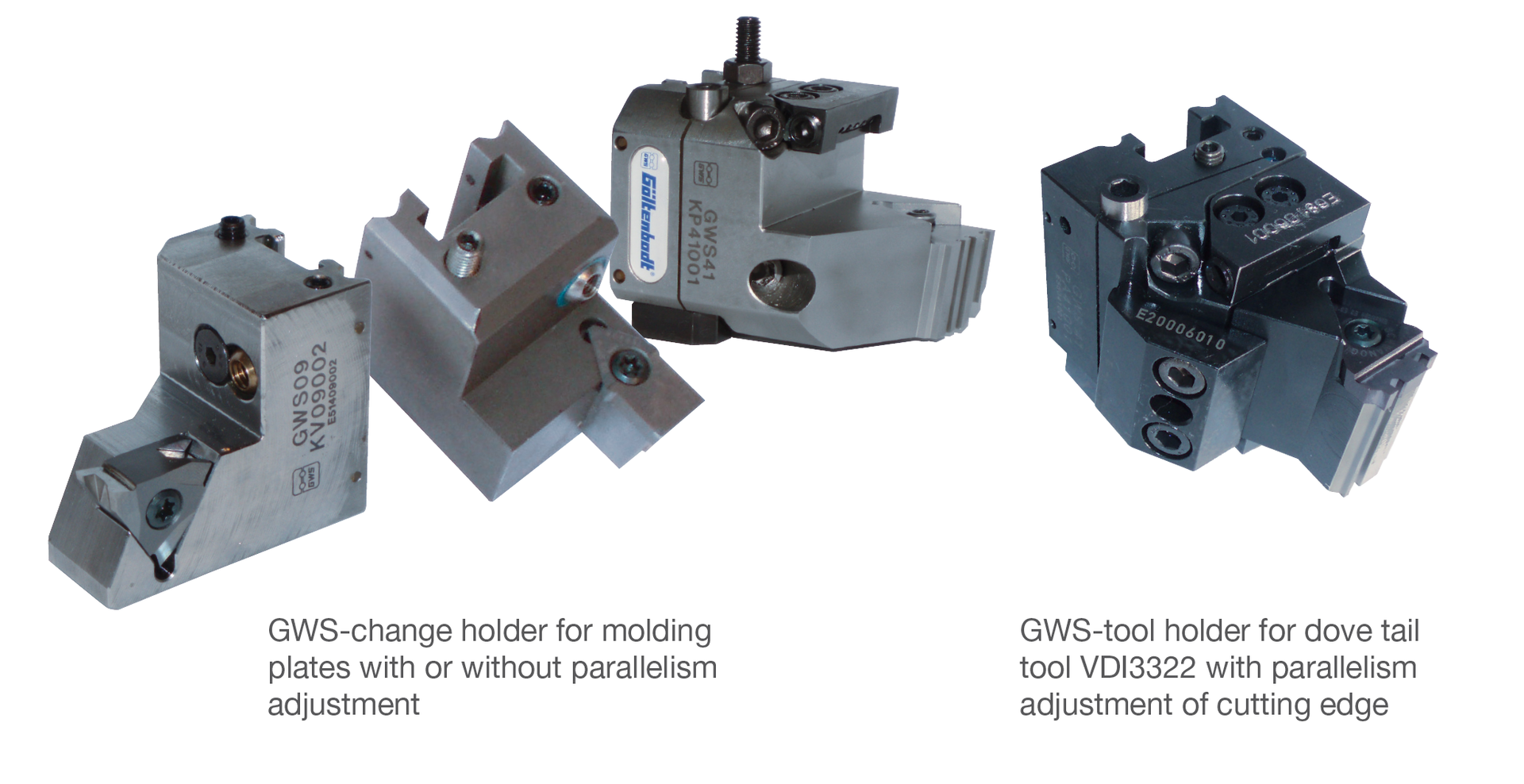

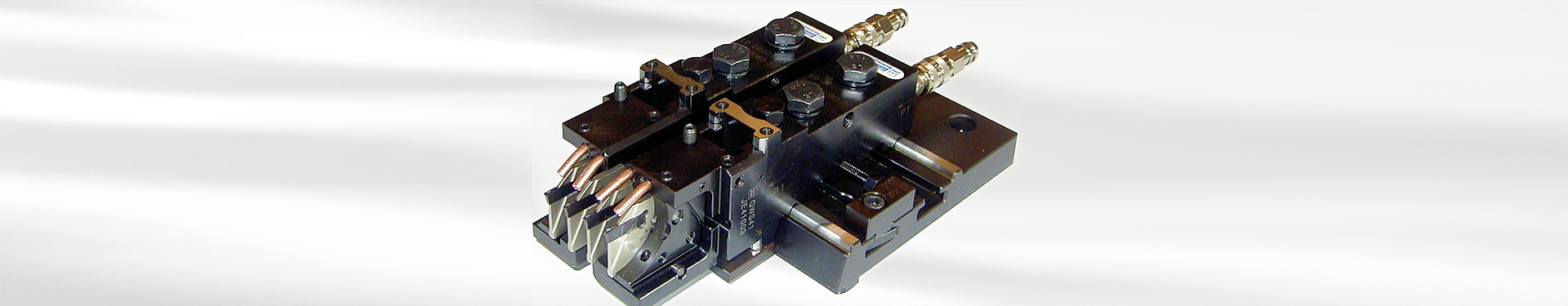

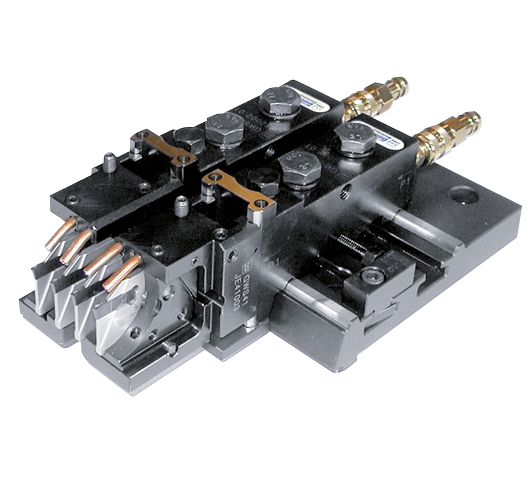

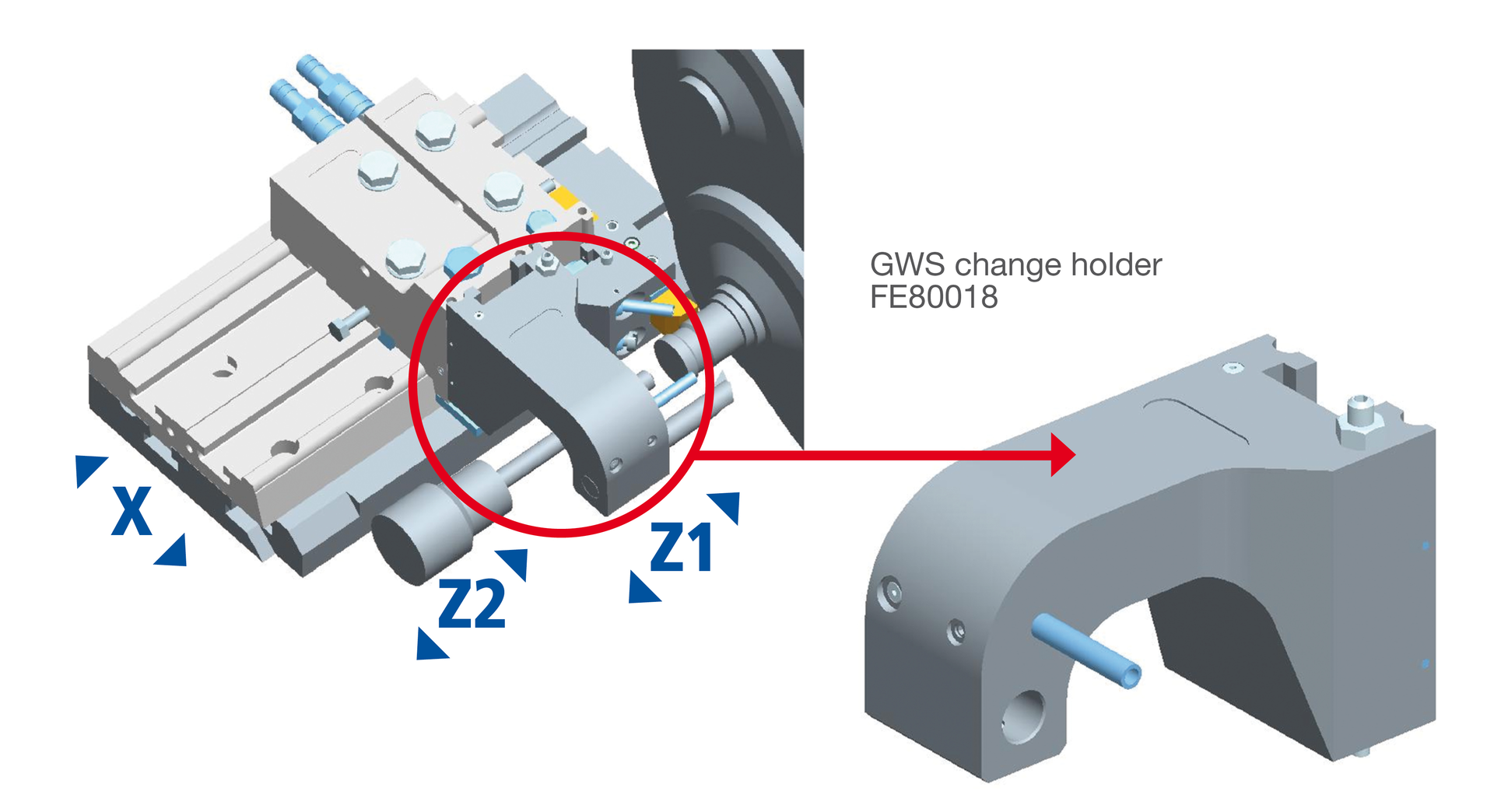

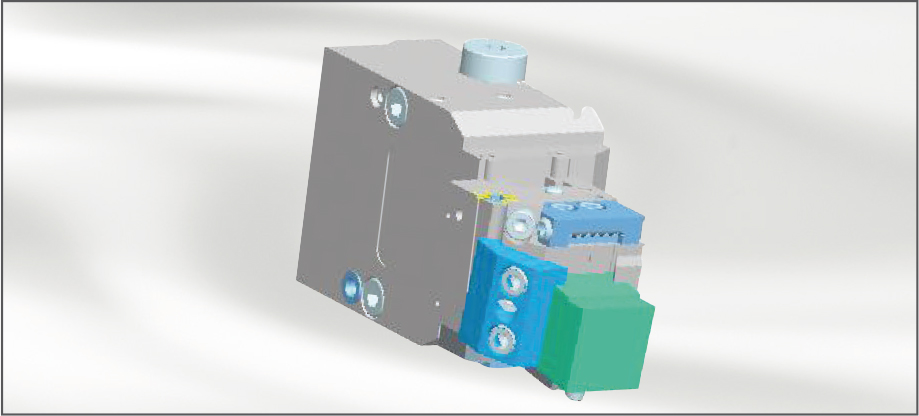

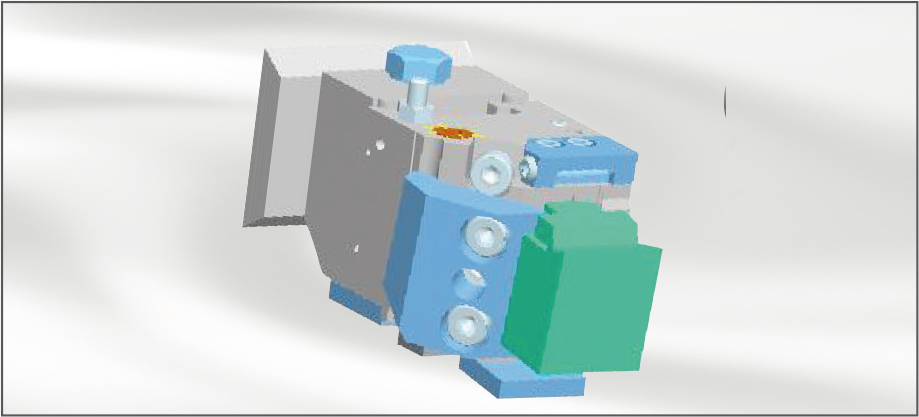

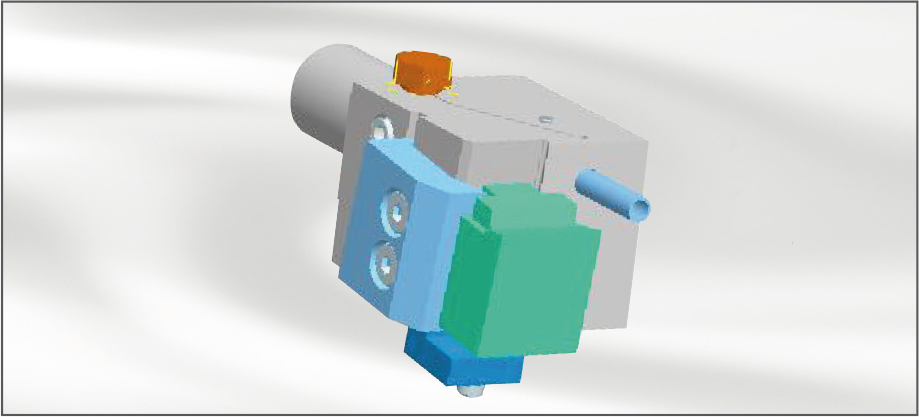

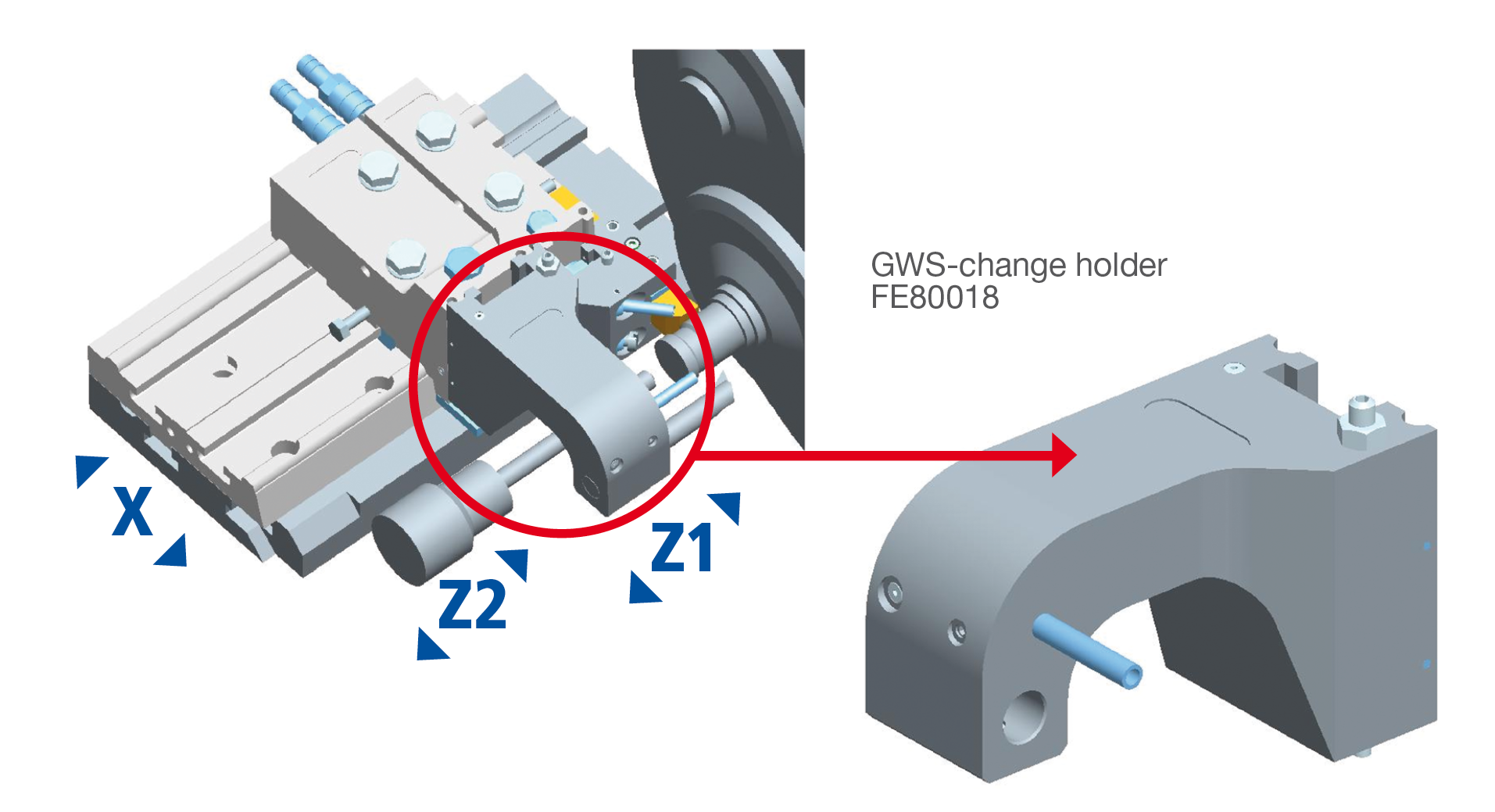

In direct comparison, copy turning was defeated. It requires almost three times as long as manufacturing by means of outside cut-off. For this reason, an increasing number of companies tend to decide in favor of recessing tools on their CNC multi-spindle and turning machines. The ideal combination of GWS-tool holder and forming tool stands for utmost form accuracy, absolute stability, very good cutting properties, extremely short processing times and serves as guarantee for a substantially increased production.

The GWS-advantages:

- Machine and cutting edge independent tool holders

- 100% outside machine in Y (swing) and parallelism adjustable

- With internal coolant supply

- Low maintenance and safe processing

- User friendly

- Robust, reliable, flexible