The GWS-Modular tool change holders, which are based on the tested and proven hydro clamp chuck technology, are an excellent example of high precision workmanship.

The hydraulic compensation has a dampening effect on the clamped tool, thus reducing process related vibrations. GWS-Modular hydro chucks are ideally suited for clamping of tools with Weldon shanks or cylinder shanks and guarantee precise and safe clamping.

Fine machining of bores necessitates perfect parallel alignment between the predrilled hole and the machining axis to ensure optimum performance of the reamers. However, when processing multiple clamping or even when simply changing tools, clock errors and positioning errors may occur and cause misalignment between tool and workpiece.

GWS-Modular floating chucks are designed for vibration free compensation of such radial and angular misalignments, thus ensuring high cutting performance and long operational life!

YOUR ADVANTAGES AT A GLANCE:

- Optimization of fine machining bores

- Compensation of lateral positioning errors and misalignment between tool and workpiece

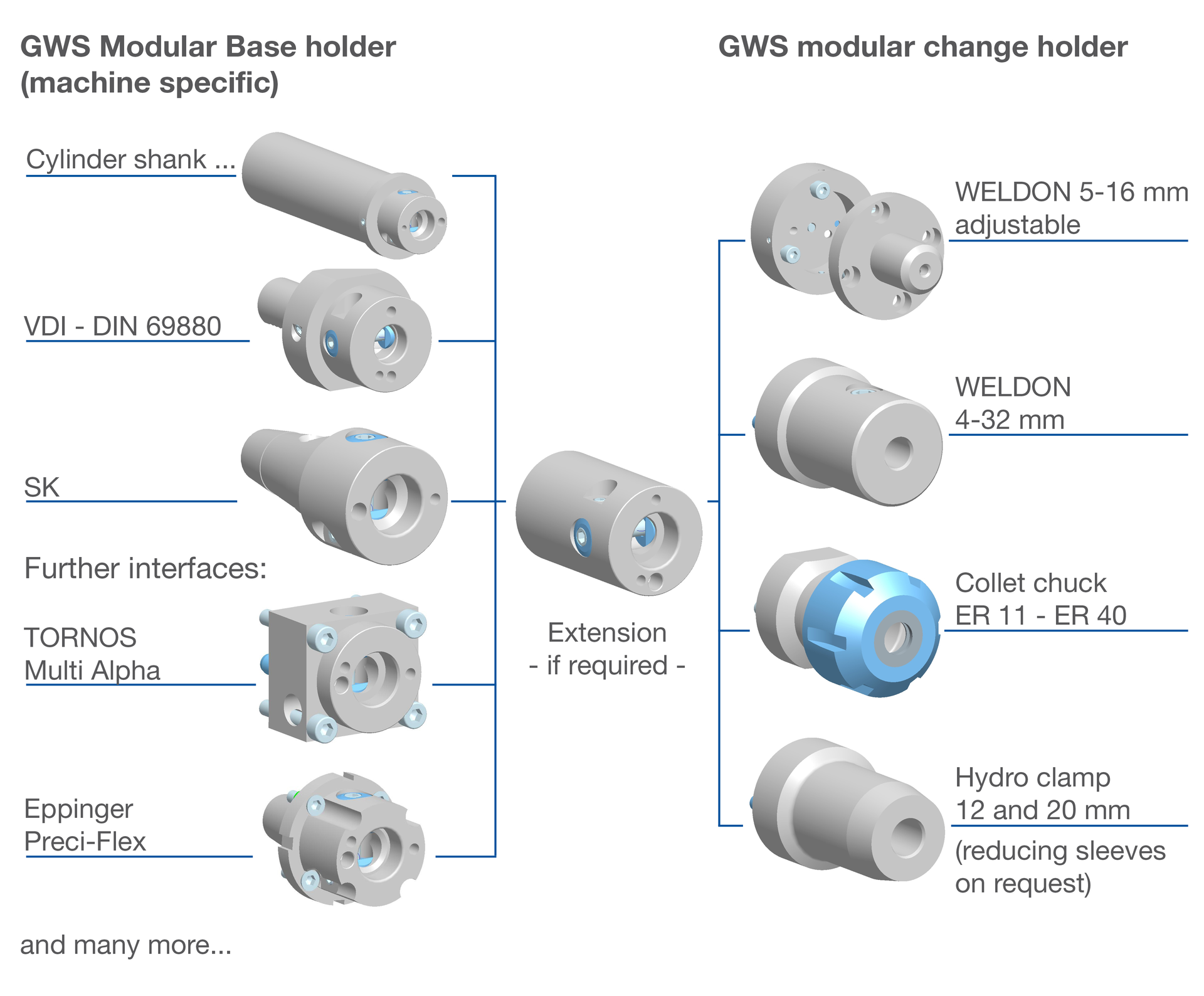

- Proven GWS Modular interfaces

- High flexibility

- Compact short design

- Utmost repeatability

- 100% pre-settable outside the machine

- Other interfaces upon request

- Internal coolant supply