Sooner or later the best solution

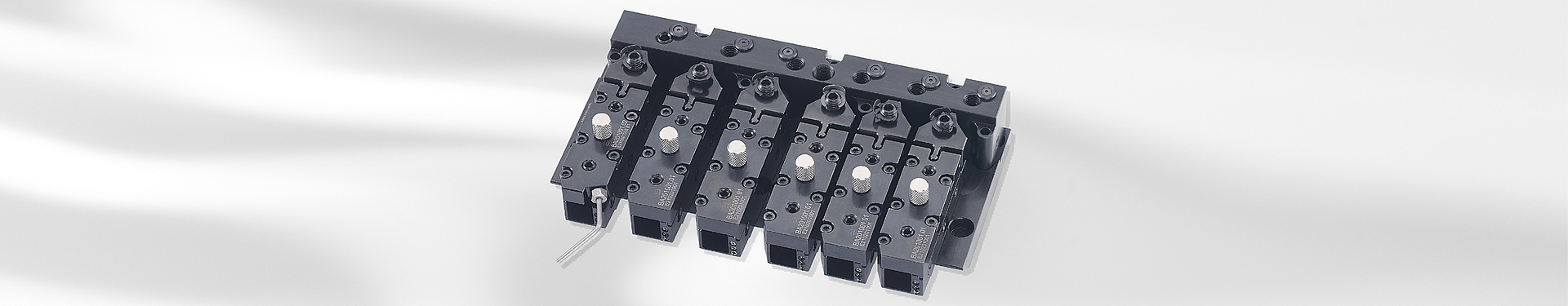

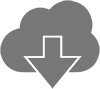

The GWS-tooling system now also offers such excellent advantages for swiss-type automatic lathes which were hitherto only available for multi-spindle automatic lathes.

ADVANTAGES:

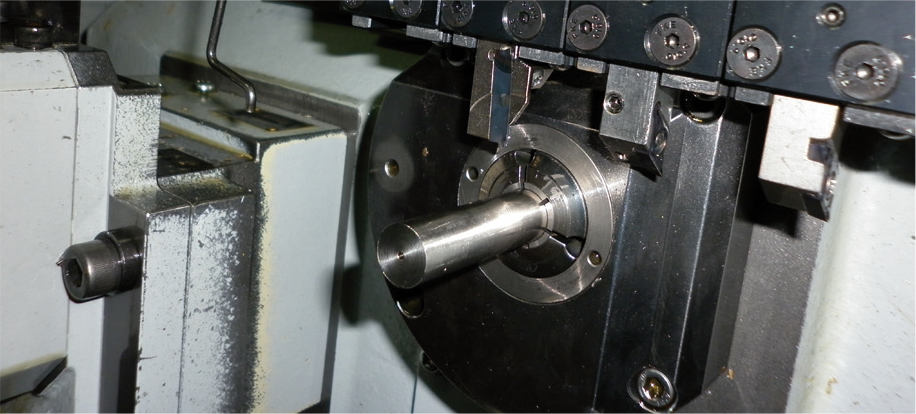

- Quick, easy and precise tool change over

- Quick change system due to GWS-column guide

- Short setup times during cutting edge changing due to preset backup tools

→ Increased productivity

- Easy and secure clamping

- Highest accuracy, repeatability better than 0.01 mm (0.0004")

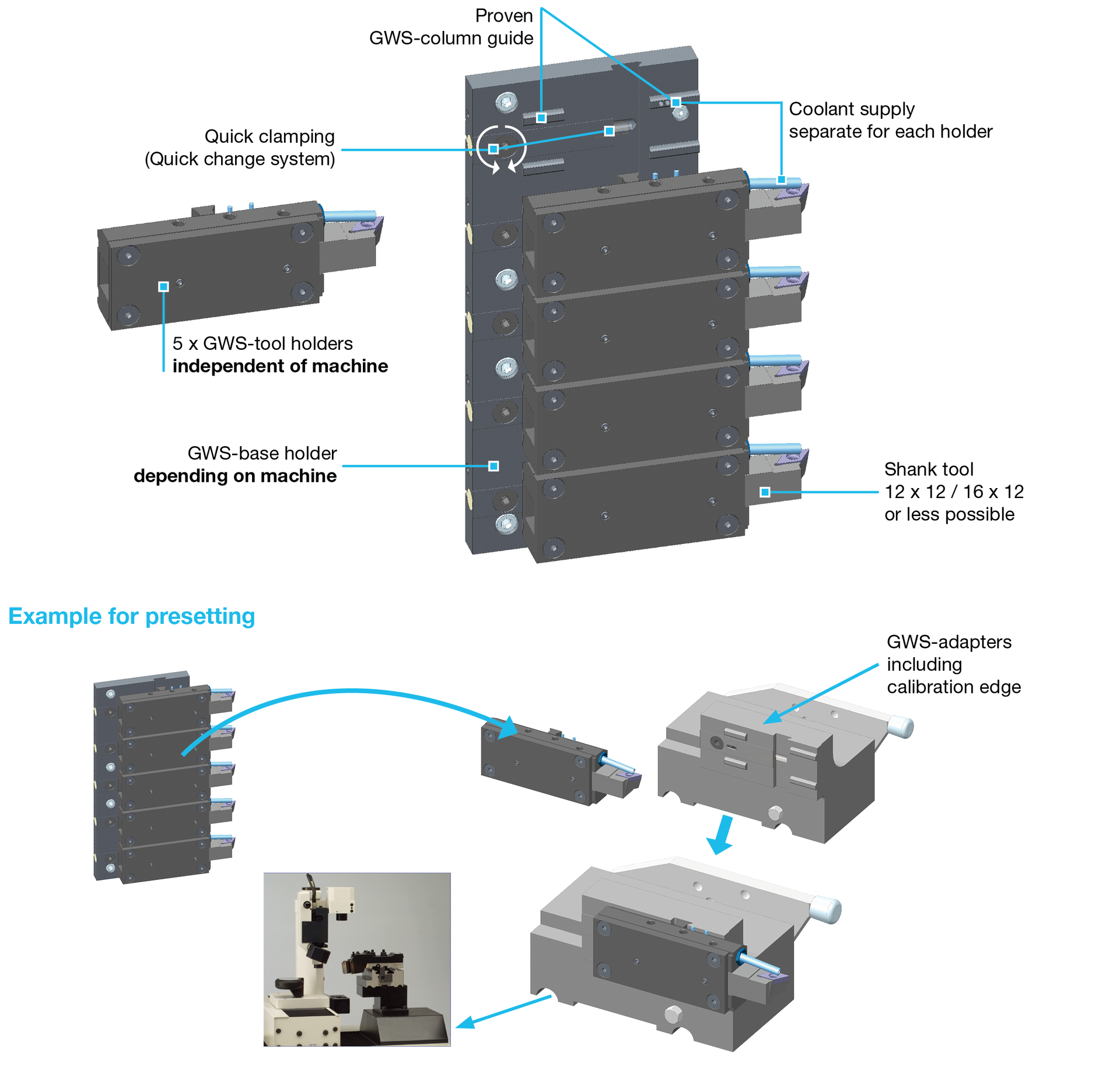

- GWS-tool change holder pre-settable off the machine tool

- Various preset concepts possible

- Exact positioning of cutting edge inside the machine

- Short setup and tool changing times → Reduced machine downtimes

- Use of standard shank tool holders possible

- GWS tool holder for 8x8, 10x10, 12x12 and 16x16 possible

- GWS tool holder for use across various machines

- Optimal flexibility for your production purposes

- Internal coolant supply up to 100 bar (1450 psi)

- Coolant supply by means of GWS-base and tool holder for every tool position

- Optimal combination of coolant supply and quick change function

- Cooling and lubrication of cutting edge directly at the processing point