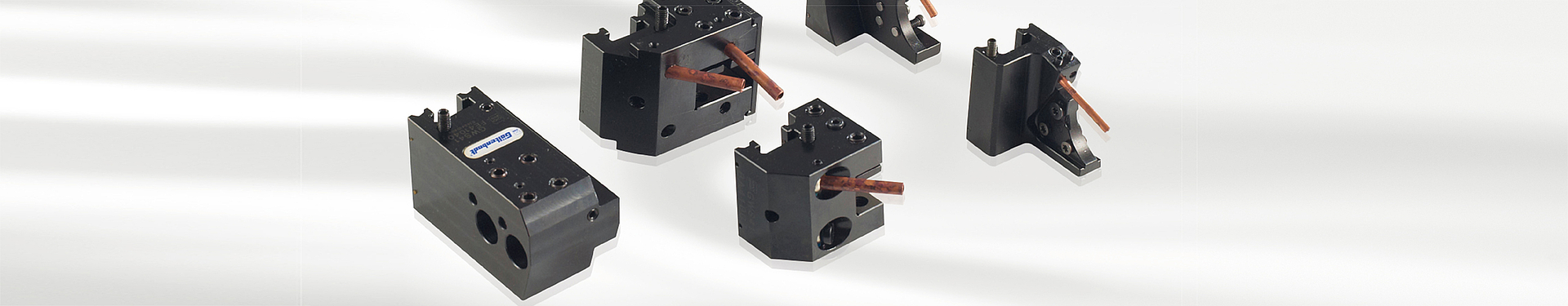

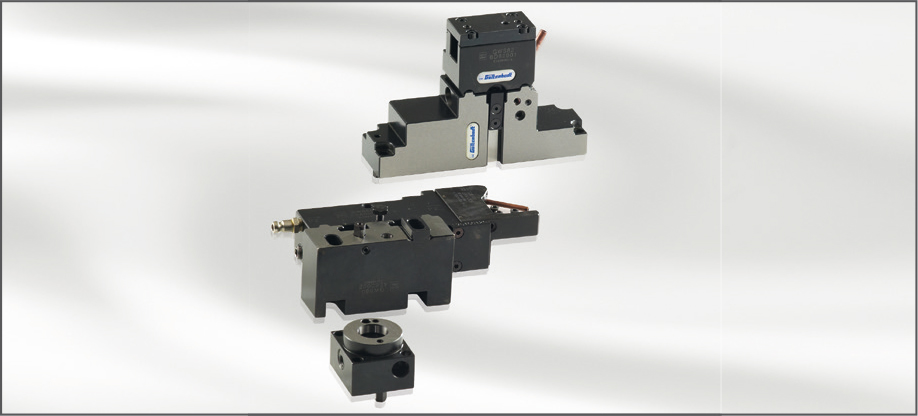

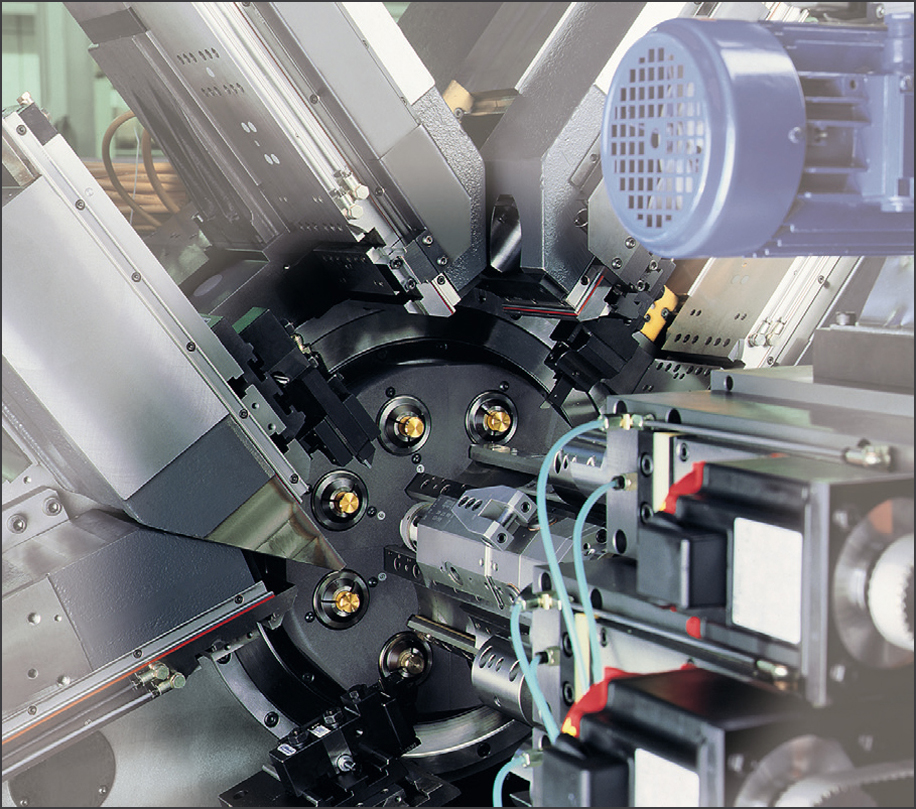

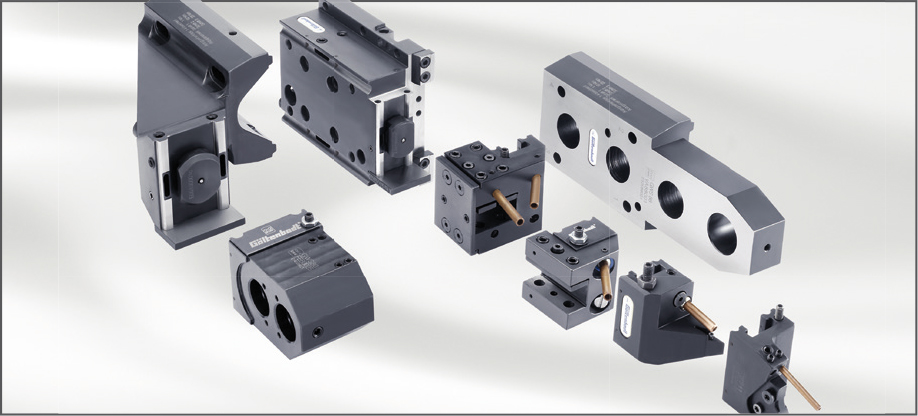

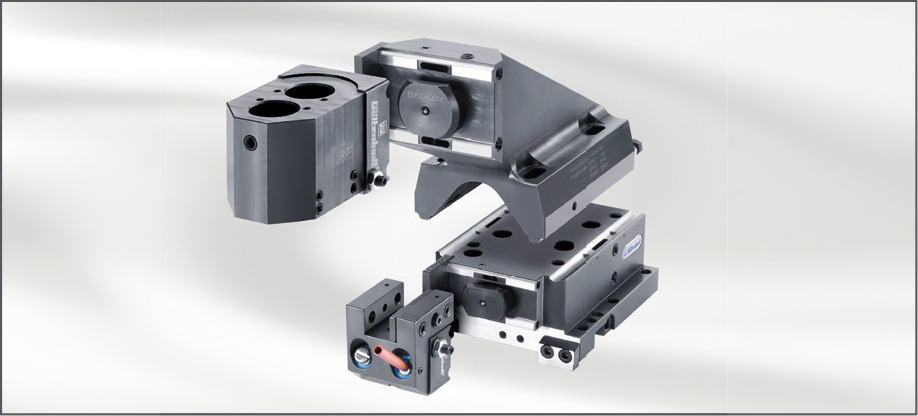

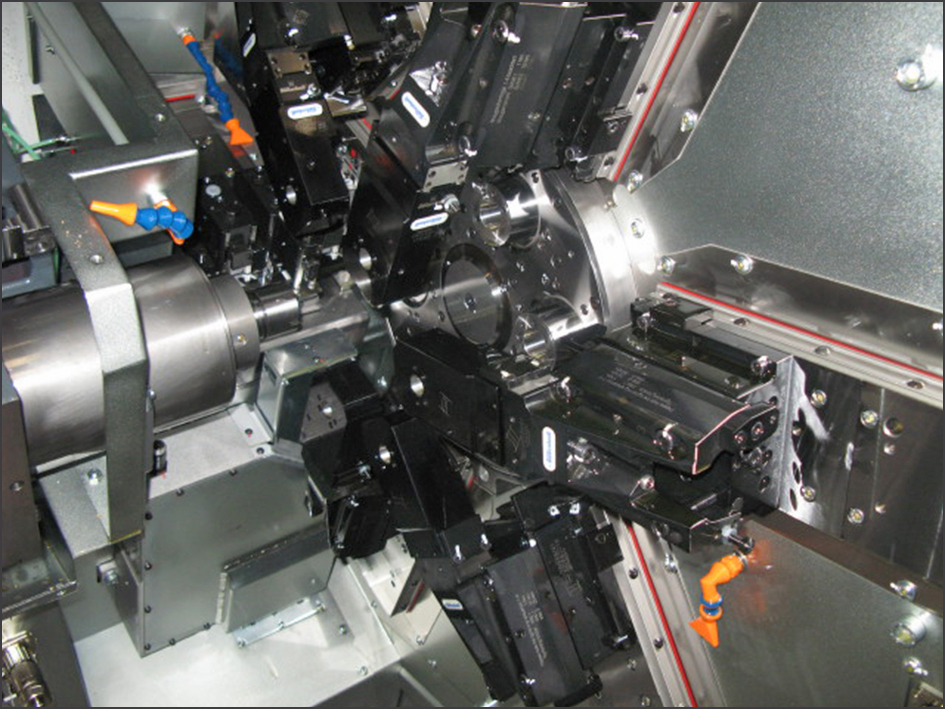

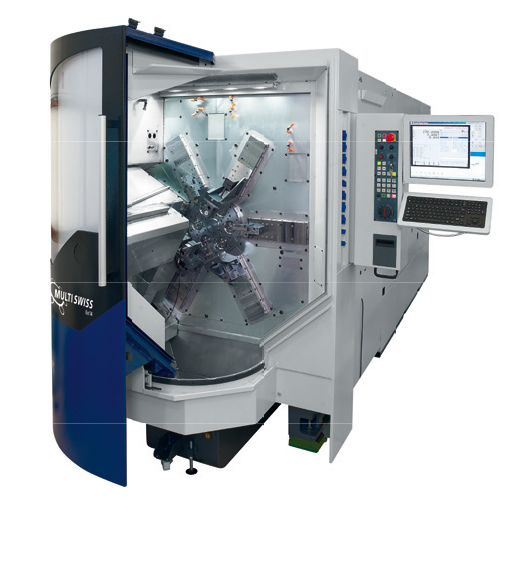

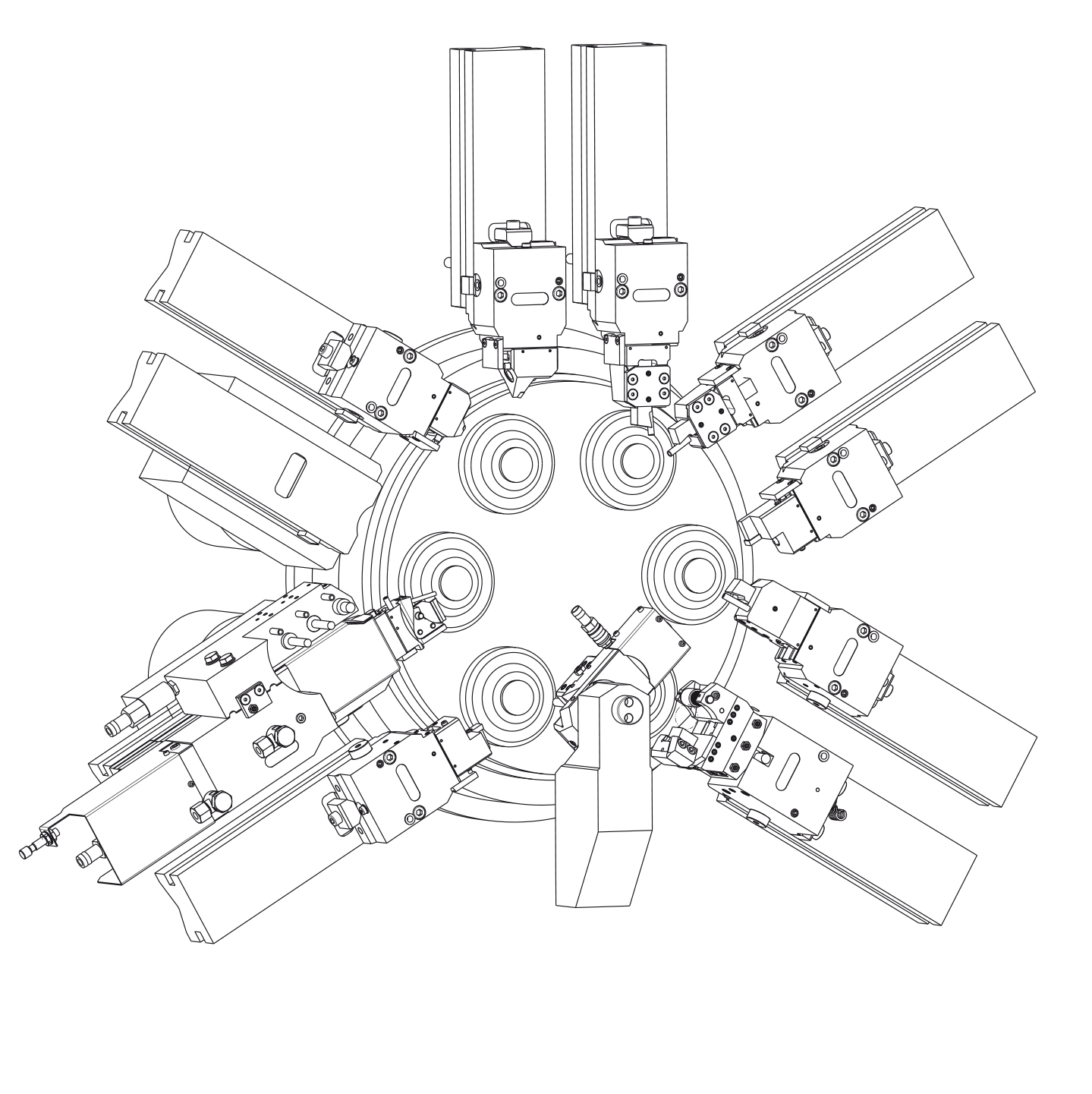

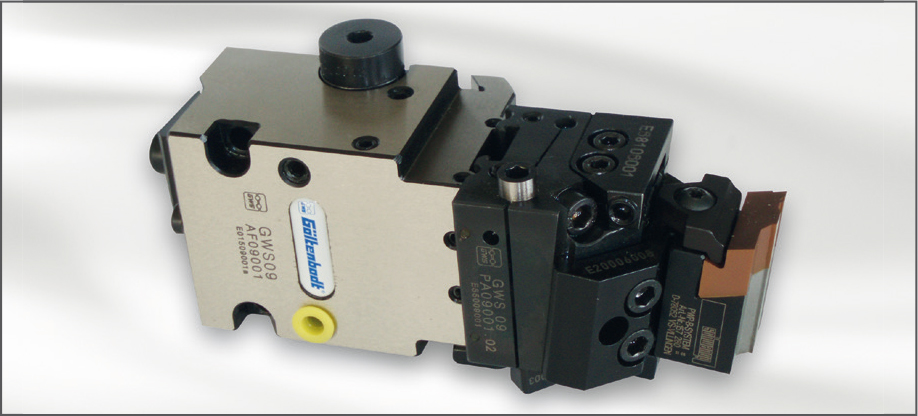

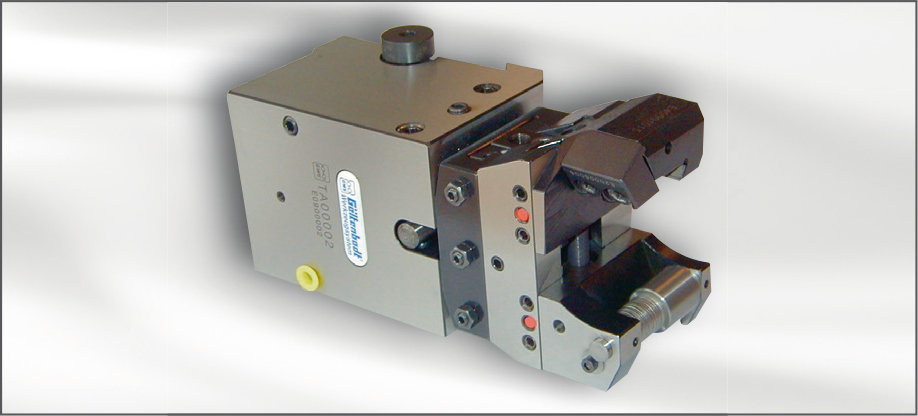

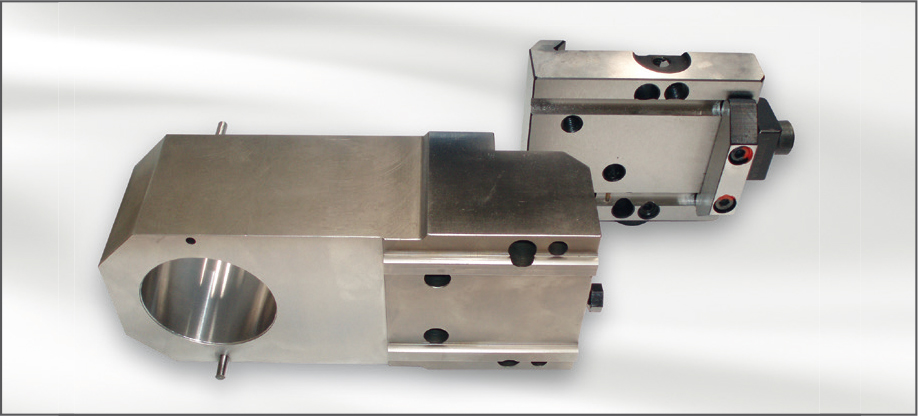

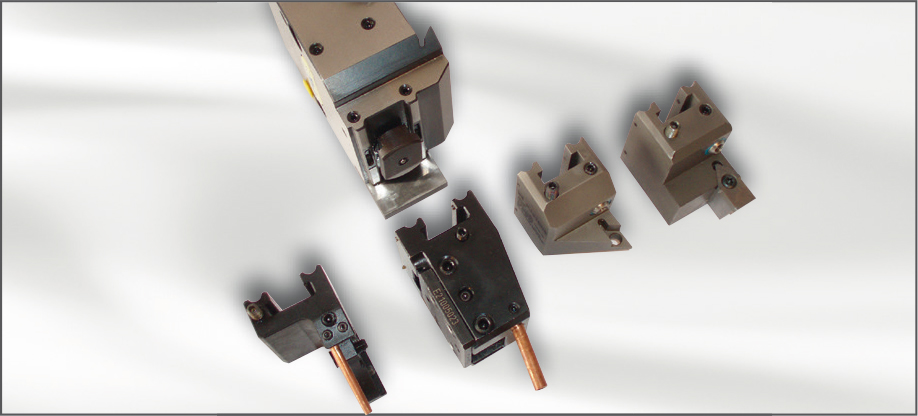

For several decades, GWS tool holder systems for multi-spindle automatic lathes have been known worldwide for highest productivity and precision. They can be preset 100% outside the machine and therefore help reduce nonproductive setup times to the absolute minimum. Products also include solutions for "classic" cam controlled turning machines as well as CNC machines with cross slides and end slide blocks such as TORNOS, SCHÜTTE, GILDEMEISTER, INDEX, TAJMAC ZPS, WICKMANN, et al.

DIE GWS-HIGHLIGHTS:

- Presettable 100% outside the machine

- Positioning – variable or 0-point Change accuracy better than 0.01 mm

- Highest repeat accuracy

- Time saving changing system

- Extremely high flexibility

- Above average service life

- Standard-GWS quick change tool holder for all types of machines

- Variable coolant management, for either high or low pressures (inside coolant supply for pressures up to 35 bar or up to 100 bar resp. possible)